Introduction

Tesla Optimus production 2025 is ramping up as the company aims to deploy thousands of humanoid robots for factory and home use. Unveiled in 2021, Optimus has evolved from prototype to production-ready, with Tesla Optimus production 2025 targeting 1,000 units by year-end. This article explores Tesla Optimus production 2025, including manufacturing milestones, applications, and market impact, based on Tesla’s Q3 2025 earnings call, Electrek reports, and Elon Musk’s X updates.

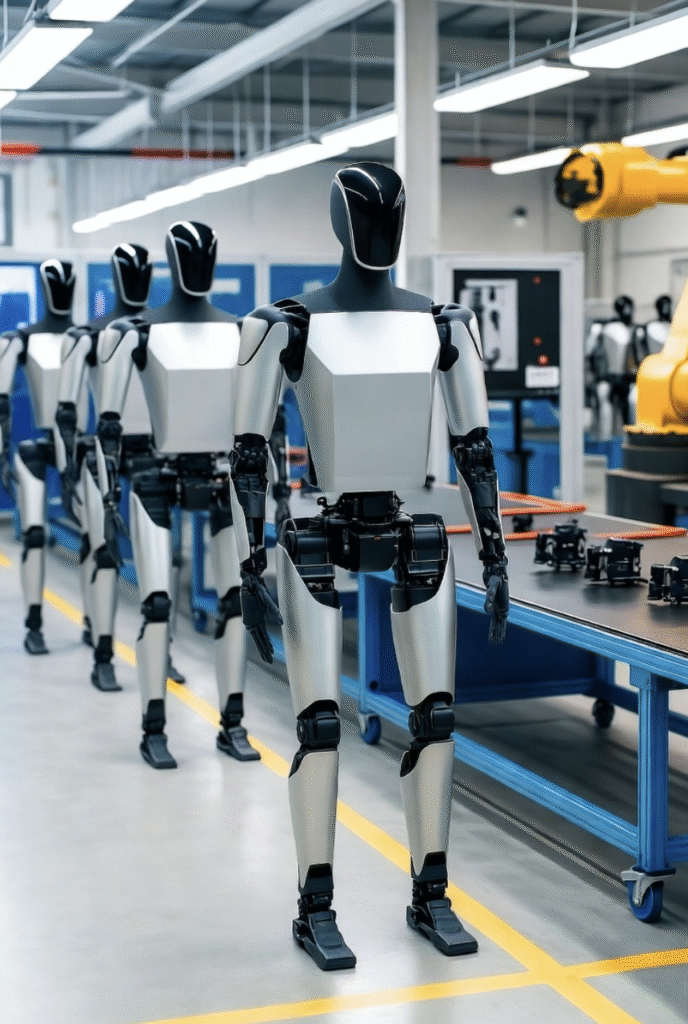

Manufacturing Ramp-Up in Tesla Optimus Production 2025

Tesla Optimus production 2025 is centered at Giga Texas, where the Gen 2 model with 40 degrees of freedom in hands is being scaled. The Q3 earnings call revealed 1,000 units planned for internal deployment by December 2025, with Musk projecting 5,000–10,000 in 2026. Tesla Optimus production 2025 uses unboxed manufacturing techniques from the Cybercab, reducing costs to $20,000 per unit. Battery life has improved 50% to 8 hours, and weight dropped to 73 kg, enabling efficient factory tasks. These advancements in Tesla Optimus production 2025 position it for rapid scaling, with Musk noting on X that “Optimus will be in limited production for Tesla internal use in 2025.”

Applications and Performance Capabilities

Tesla Optimus production 2025 focuses on practical applications, starting with factory automation at Tesla plants. The robot can assemble battery packs, boosting efficiency by 25%, as demonstrated in internal videos. For homes, Tesla Optimus production 2025 includes chores like cleaning and folding laundry, with AI trained on Dojo’s legacy processing 100 commands per second. The Q3 report highlighted Optimus integrating with xAI’s Grok for natural language interaction, making Tesla Optimus production 2025 a multitasking marvel for industrial and consumer markets.

Market Impact and Economic Implications

Tesla Optimus production 2025 could automate 15% of repetitive jobs, per CNBC, revolutionizing manufacturing and caregiving. Priced at $25,000, it undercuts competitors like Boston Dynamics’ Atlas ($150,000+). Analysts from Ark Invest forecast Optimus contributing $1 trillion to Tesla’s valuation by 2030, with Tesla Optimus production 2025 as the foundation. The earnings call projected 50,000 units in 2026, capturing early market share in a $38 billion humanoid robot industry by 2032.

Challenges in Scaling Tesla Optimus Production 2025

Tesla Optimus production 2025 faces hurdles like supply chain constraints for actuators and regulatory approval for home use. The Verge notes safety concerns over job displacement, prompting Tesla to implement strict AI safeguards and retraining programs. Musk addressed this on X, promising transparent testing by Q4 2025. Battery and sensor costs remain high, but 4680 cell efficiencies from Q3 (12.5 GWh deployments) will aid Tesla Optimus production 2025 cost reductions.

Future Roadmap for Tesla Optimus Production 2025

Looking beyond, Tesla Optimus production 2025 sets the stage for 2026 mass production, with Musk forecasting 100,000 units. Integration with Robotaxi networks for delivery tasks is planned, expanding applications. The Q3 call teased Optimus V3 with improved dexterity, solidifying Tesla Optimus production 2025 as a leader in humanoid robotics.

Conclusion

Tesla Optimus production 2025 is transforming robotics, with 1,000 units targeted for internal use and applications in factories and homes. As Tesla scales manufacturing, the impact on productivity will be significant. Stay tuned to EnergyFutureAI for more on Tesla Optimus production 2025 developments. For related insights, see our article on Tesla Q3 Earnings Reaction 2025: What It Means [https://energyfutureai.com/tesla-q3-earnings-reaction-2025].

Sources: